Machine Description:

PC-600B is multifunctional positioning machine for the rigid box and book cover. PC-600B can make positioning for the shoe box, tea box, cosmetic box, chocolate box, watch box, jewelry box, gift box, perfume box, mobile phone box, lever arch file, hardcover book , Photo album, eyeshadow case etc.

>

Technical Parameter

Model No | PC-600B |

Paper size

| Length:140-1100mm Width:100-680mm |

Paper Thickness | 80-300g/㎡ |

Max Box size | L500*W400*H120mm |

Min Box Size | L65*W65*H15mm |

Cardboard thickness | 1-4mm |

Max Case Size | L1000*W500mm |

Min Case Size | L130*W70mm |

Separated cardboard Quantity can put | 1-6pcs |

Middle Strip size | 10mm |

Production speed | 20-35pcs/min |

Positioning Precision | +-0.1mm |

Motor Power | 9kw/380V 3phase |

Air supply | 10L/min 0.6Mpa |

Heating Power | 6kw |

Machine dimension | L8000*W4000*H2050mm |

Machine Weight | 2600kg |

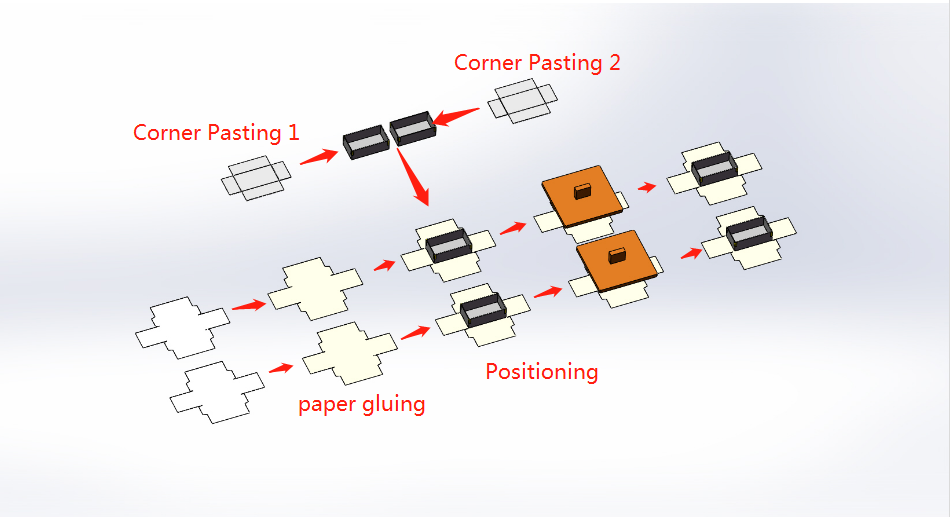

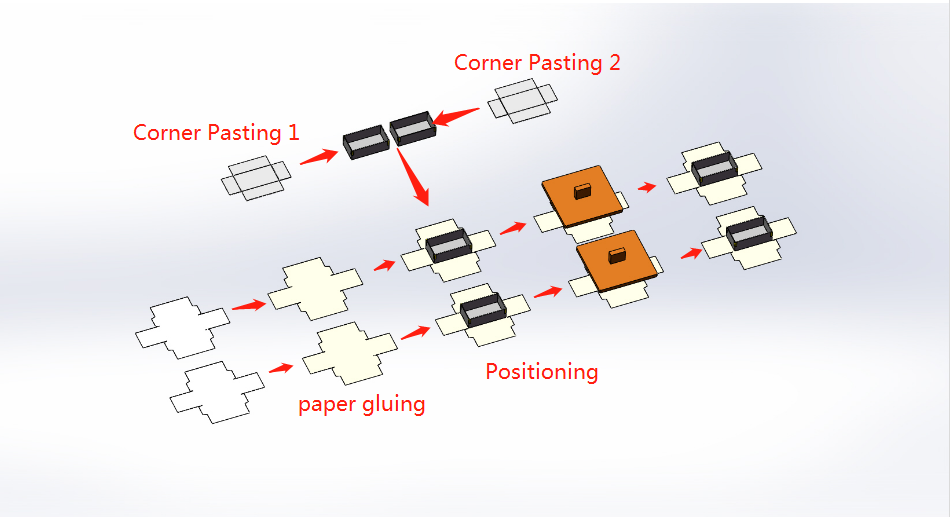

Production Flow

Machine Detail Display

Machine Application

Machine Structure Features

● Camera Positioning System

Camera positioning and mechanical arm clamping box to achieve high-precision positioning.

● Digital Adjustment Of Sizes

Adopt new design of serve and pneumatic structura to wrap the box,fast digital acjustment of sizes.

● Servo Controlled Paper Feeder

New designed serve controlled paper feeder adopts post-sucking pre-pushing type to convey paper which efficiently avoids two pieces of papers entering into the machine.

● Line-touch Designed Copper Scraper

The copper scraper cooperates with the glue roller by line-touch design which makes the scraper more durable.

● Glue Viscosity Meter (Optional)

Auto glue viscosity meter efficiently adjusts the glue stickiness which ensures the quality of finished products.

Pre-sales Questions

01. Is your company is trader or factory?

We are the direct manufacturer of the rigid box and book cover making machine with 16 years experience.

02. Where is your company in china?

Our Factory located in Zhongtang Town, Dongguan City, Guandong Province, China. We are near to shenzhen airport and guangzhou airport.

03. What does your machine make?

Our machine is to make the shoe box, tea box, cosmetic box, jewelry box, gift box,watch box, mobile phone box,gift box,flower box , belt box,chocolate box, sweet box, lever arch file cover, hardbook cover. Hardcover making etc.

04. What are the main spare parts used in your machine?

Our machine used the high end spare parts in our machine, like the Panasonic PLC, the Omron Relay, the schneider electronics, the Delta Servo motor&drive, the Airtac Cylinder&walves, the Yamaha Robotic Arm, Dell Computer etc.

05. How to offer the after sale service if we purchase your machine?

All our machine has english manual and video operationing video for support customer installation and training. If customer need technician come to their country for training, we have technician team for overseas training.

06. How to recommend products?

We have nearly 20 products . We can also provide non-standard equipment production and new product development services according to customer requirements. According to the customer's requirement to be produced, the purpose of the product to be purchased, the environment, the purchase volume and other related conditions, we will recommend several cost-effective products for the customer to choose.

07. How to make a quotation?

Based on our company's research and development costs, production costs and customer purchases, we conduct calculations to determine the price of the product.

08. If we send the box paper and cardboard, Your machine can make a trial running?

Yes, we can try your box run in our machine, we can make the box mold for your for free.

Problems in Sale

01. About payment

After signing the contract, 30% of the total payment will be paid in advance, 70% should be paid before machine shipment.

02. About delivery time

About 7-15 working days after receiving the deposit. the factory will re-decide whether to change the delivery date when the order is confirmed. The standard machine is generally within 7 working days after receiving the deposit.

03. Order tracking

After the customer places an order, our company will send professional personnel to track the order and regularly report the production progress to the customer.

04. Product testing

During the production process, our company will adopt strict inspection process to ensure product quality. Through internal inspection, we ensure that the components produced by our company meet the technical requirements; through external inspection, we ensure that the components produced by our company are not subject to quality problems; and then pass the whole machine inspection to ensure that the mechanical equipment meets the technical production requirements .

05. Product packaging

Before the product is shipped, it will be packed by film and then we will use the plywood case for the package.

06. Product Transportation

Products are generally shipped from Shenzhen Port, China to the destination port by sea

After Sales Question

01. Shelf life/warranty period of the product

The product warranty period is generally one year, and our company provides lifetime maintenance services. If the machine has quality problems, our company will help the customer to solve it through the following ways: a. Send spare parts to the customer. b. Remotely assist customers in maintenance. c. Notify our agent company to send personnel to the customer's factory for maintenance. d. Our company directly dispatches relevant personnel to the customer's factory for maintenance.

02. About transportation damage

In the process of product transportation, if product damage occurs, it is determined that our product packaging and reinforcement work is not in place, and our company will bear the corresponding losses.

03. About machine maintenance

We will contact customers on a regular basis on how to maintain and maintain the machine. For domestic customers, we will have a master to provide on-site service.

04. Problems during use

If there is any problem in the process of using the product, the customer can directly call or send an email to our after-sales department (24-hour hotline). The personnel of our department will respond immediately and make a decision on the response measures within 24 hours.

English

English