In the competitive box manufacturing industry, efficiency and quality are key to success. Whether you're producing gift boxes, jewelry boxes, or cosmetic packaging, choosing the right machinery can significantly improve your production process and help your products stand out. In this article, we'll explore the essential machines for box manufacturing, their functions, and how to choose the best ones for your business needs.

Understanding Box Types

Rigid Boxes vs. Other Types

Rigid boxes are known for their durability and premium appearance, setting them apart from folding cartons and corrugated boxes:

· Folding Cartons: Lightweight and typically used for everyday packaging.

· Corrugated Boxes: Strong and ideal for shipping.

· Rigid Boxes: Offer a luxury feel and robust structure, perfect for high-end products.

Common Applications

Rigid boxes are highly valued in industries that prioritize aesthetics and durability, such as:

· Gift Packaging: For premium gifts and seasonal items.

· Jewelry Storage: Protecting and presenting valuable pieces.

· Cosmetics Packaging: Elevating the appeal of luxury skincare and beauty products.

Key Machines for Box Manufacturing

Cutting Machines

· Functionality: Cutting machines precisely shape raw materials into desired sizes, forming the foundation of a high-quality box.

· Types:

o Die-Cutting Machines: Best for high-volume production with intricate designs.

o Laser Cutting Machines: Offers unmatched precision and flexibility for custom projects.

· Purpose: Grooving machines create precise lines that allow clean, easy folding for rigid boxes.

· Process Overview: Grooves ensure the box maintains a professional finish without damaging the material.

· Role in Assembly: Gluing machines secure box components, ensuring durability and functionality.

· Automation Levels: Available in manual, semi-automatic, and fully automatic options to suit different production needs.

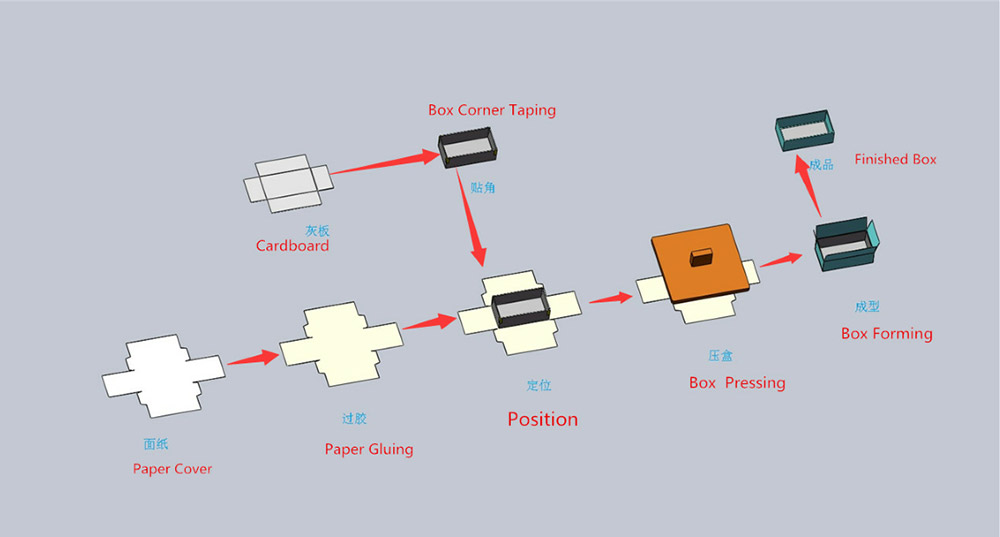

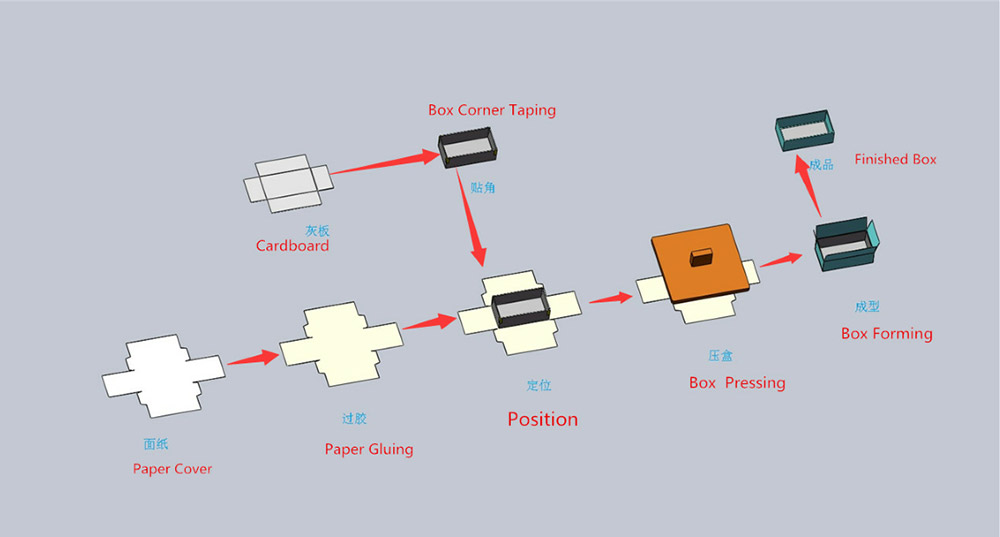

· Overview: These machines bring the box to life by assembling and shaping it into its final form.

· Features to Consider: Look for adaptability to various sizes, high-speed performance, and ease of operation.

Choosing the Right Machine

Production Volume

Small-scale operations may find semi-automatic machines sufficient, while fully automated systems are ideal for handling high production volumes.

Types of Materials

Different materials, such as thick cardboard or specialty paper, require machines designed to accommodate their properties.

Budget Constraints

Investing in advanced machinery may involve a higher initial cost but offers long-term benefits through increased efficiency, reduced labor costs, and minimized waste.

Advanced Machinery Options

· Benefits: Fully automatic machines provide unmatched speed, precision, and labor efficiency, making them ideal for large-scale production.

· Examples of High-Speed Models: These models combine cutting, grooving, and gluing functionalities for streamlined operations.

· Semi-Automatic Machines: Offer flexibility and affordability, making them suitable for smaller businesses.

· Fully Automatic Machines: Optimize large-scale manufacturing by maximizing output and consistency.

Maintenance and Support

Importance of Regular Maintenance

Routine maintenance is essential to keep machines operating efficiently. Regular inspections, timely replacement of worn parts, and proper cleaning extend the lifespan of your equipment.

Technical Support

Choose a manufacturer that offers robust after-sales support, including training, spare parts availability, and prompt technical assistance. This ensures smooth operations and minimizes downtime.

Conclusion

Selecting the right machinery is crucial for manufacturers aiming to achieve efficiency and maintain high production standards. By assessing your specific needs—such as production volume, material type, and budget—you can invest in machines that will help your business thrive.

Why Choose Dongguan Pinchuang Automation Equipment Co., Ltd.?

Since 2015, Dongguan Pinchuang has been a leader in rigid box manufacturing. Operating a 5,000-square-meter factory with a team of over 50 experts, we specialize in automatic rigid box and case-making machines. Our products are CE and EAC certified, ensuring global compliance and quality standards.

Trusted by clients across Europe, South Africa, the Middle East, and Southeast Asia, we deliver tailored solutions for industries ranging from cosmetics to stationery.

Contact us today to discover how our innovative machinery can transform your box production process and elevate your business to the next level!

English

English