As an automatic rigid box machine manufacturer, we understand that making the perfect paper box is both an art and a science. Our mission is to help businesses and individual creators produce high-quality, professional paper boxes that are functional, beautiful, and scalable. In this beginner's guide, we'll walk you through everything you need to know, whether you're crafting by hand or interested in the benefits of automation.

Why Rigid Box Crafting Matters in Today's Market

In today's packaging market, paper boxes are more than just containers—they're a way to make a statement. With rising demand for sustainable and visually appealing packaging, paper boxes have found their place across industries, from luxury goods to small-scale handmade products.

For beginners, crafting a perfect paper box by hand can be a rewarding experience. However, for businesses looking to meet high production demands, automated rigid box machinery offers the scalability and quality consistency that only advanced technology can provide. In this guide, we share the foundational steps of paper box crafting, enriched with insights into how rigid box machines can elevate your production process.

1. Tools and Materials Needed for Paper Box Making

Essential Tools for Beginners and Professionals

When starting, having the right tools is essential for achieving precision and durability. Key tools include:

· Cutting tools: Sharp scissors or a cutting knife for clean edges.

· Scoring tools: These are used to make precise folds without damaging the paper.

· Ruler and grid mat: For accurate measurements.

· Glue or adhesive: High-quality adhesives suited for paper bonding.

For large-scale production, rigid box machines incorporate all these functions, from cutting and scoring to folding and gluing, in a single automated system. This saves time, ensures precision, and drastically reduces material waste, all while meeting high production demands.

2. Choosing the Right Paper Types for Professional-Looking Boxes

Not all paper types are suited for box making, as the weight, flexibility, and finish affect the final result. Here are some recommended types:

· Cardstock: A sturdy option, ideal for basic gift and storage boxes.

· Kraft Paper: Offers a rustic, eco-friendly look, popular for sustainable brands.

· Specialty Papers: Textured, metallic, or embossed papers add an element of luxury.

With our rigid box machines, you can efficiently work with various paper types, as the equipment's versatility accommodates everything from lightweight cardstock to heavier specialty materials. By automating the process, you get consistent, high-quality results across different paper types without compromising speed or precision.

3. Mastering Basic Folding and Cutting Techniques

Crafting a paper box by hand requires mastering fundamental folding and cutting techniques. Here are the basics:

· Measuring and cutting: Start by measuring and cutting your paper accurately.

· Scoring for clean folds: Score the paper where folds are needed to prevent tearing.

· Securing edges: Use adhesive sparingly along edges to ensure clean, firm joins.

In an automated setting, rigid box machines carry out these steps with exact precision. They are designed to cut and fold materials seamlessly, eliminating the risk of human error and speeding up the process while maintaining uniform quality across each box.

4. Step-by-Step Guide to Making a Simple Paper Box

Making a Simple Box by Hand

1. Measure and cut your paper according to the size and shape you need.

2. Score along fold lines to create crisp edges.

3. Fold each side carefully, ensuring accuracy.

4. Apply adhesive to join the sides, pressing down for a secure hold.

5. Decorate or add finishing touches as desired.

Comparison with Automated Production

Automating this process with rigid box machines takes the manual effort out of crafting. The machine's precise measurements, consistent folding, and automatic application of adhesive mean every box is flawless and completed in seconds, not minutes.

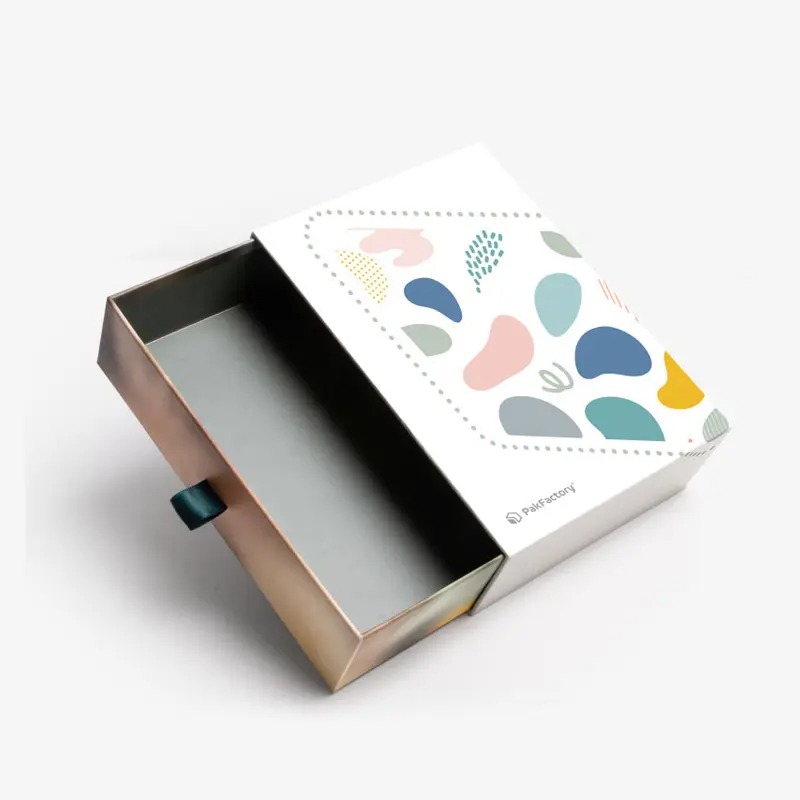

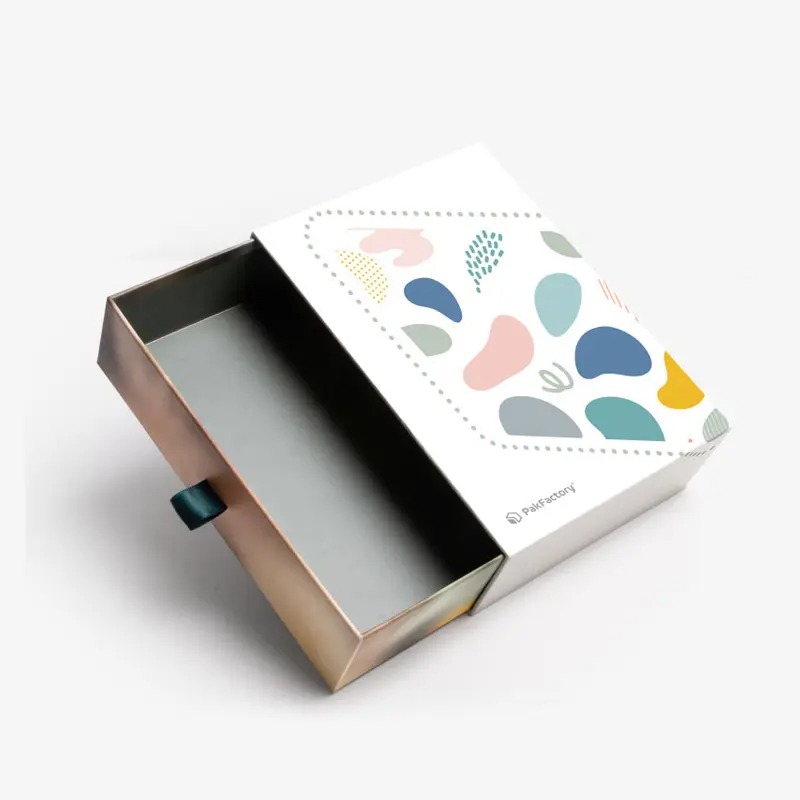

5. Adding Decorative Elements to Enhance Your Box Design

A beautifully decorated box stands out and enhances the unboxing experience. Here are some decoration ideas:

· Printed designs or logos: Use stamps, prints, or custom designs to personalize boxes.

· Embossing and foil stamping: For a luxury touch, embossing and foil accents add elegance.

· Ribbons and embellishments: Small touches like ribbons and tags can make all the difference.

When producing at scale, rigid box machines can incorporate these decorative elements automatically. Advanced machines are equipped to emboss, stamp, and even integrate customized branding, making each box unique without extra labor.

6. Advanced Techniques for Paper Box Crafting

For those ready to take their box-making skills up a notch, here are some advanced techniques:

· Complex shapes and closures: Try designs with magnetic or button closures.

· Double-layered or reinforced boxes: Ideal for fragile or high-end products.

· Custom inserts: Add compartments or padded inserts to protect contents.

With rigid box machines, you can create these advanced designs effortlessly. High-end machines can accommodate intricate shapes, durable layers, and even custom inserts, enabling complex structures that provide better protection and aesthetics.

7. Tips for Choosing the Right Paper Box Design

When selecting a design, consider the box's purpose and your audience. Here's a quick guide:

· Gift boxes: Choose a visually appealing design with bright colors or patterns.

· Storage boxes: Go for durability, with reinforced edges and thicker materials.

· Luxury boxes: Use specialty paper, embossed finishes, and elegant shapes.

If producing for a brand, consider rigid box machines to standardize design while customizing elements such as color and finishing. Automated production means every box looks uniform, reflecting brand quality and attention to detail.

8. Selling and Marketing Your Paper Boxes

Creating a beautiful box is only the first step—success also depends on effectively marketing and selling your product. Here are some tips:

· Showcase unique designs: Use quality photography to highlight special features.

· Emphasize eco-friendliness: With rising demand for sustainable packaging, promoting eco-friendly aspects can attract more customers.

· Leverage social media and marketplaces: Platforms like Instagram and Etsy are ideal for showcasing handmade and custom boxes.

For businesses scaling up, automated rigid box machines offer the quality and production volume needed to meet demand. With this consistency, you can confidently market your product, knowing each box reflects the same high standards.

The Future of Paper Box Crafting with Automated Rigid Box Machines

From handcrafting beautiful boxes to leveraging rigid box machinery for bulk production, the possibilities in paper box making are vast. As an automatic rigid box machine manufacturer, we're committed to helping you achieve perfection in every box, whether you're creating a few custom pieces or producing on a large scale. By combining traditional techniques with modern automation, you can elevate the quality and appeal of your paper boxes, ready to impress in today's competitive market.

English

English