1. Introduction

The modern packaging industry has seen remarkable advancements in recent years, especially in the realm of automatic rigid box forming. As e-commerce and global trade continue to expand, companies require ever more sophisticated packaging solutions that meet high-quality standards while staying cost-effective. Among the many factors driving this evolution, the use of high-performance materials stands out as a central pillar. These materials not only enhance the structural integrity and durability of rigid boxes but also help streamline automated production processes. In this article, we explore the application and development of high-performance materials in automatic rigid box forming and how they are shaping the next generation of packaging solutions.

2. Understanding High-Performance Materials in Automatic Rigid Box Forming

High-performance materials refer to specialized substrates engineered or treated to exhibit superior qualities such as increased strength, improved durability, and enhanced functionality under varied conditions. In rigid box forming, the use of such materials has a direct influence on:

1. Structural Stability: Better resistance to bending, crushing, and tearing

2. Production Efficiency: Fewer defects and consistent feed in automated machines

3. Brand Appeal: High-end finishing options that elevate product presentation

In automated production environments, these materials must also be consistent in thickness, texture, and handling characteristics. This ensures that the machinery can run at optimal speeds without causing jams, misfeeds, or alignment issues.

3. Major Categories of High-Performance Materials

The packaging industry employs a range of high-performance materials designed for durability, visual appeal, and sustainability. Below are some of the common categories:

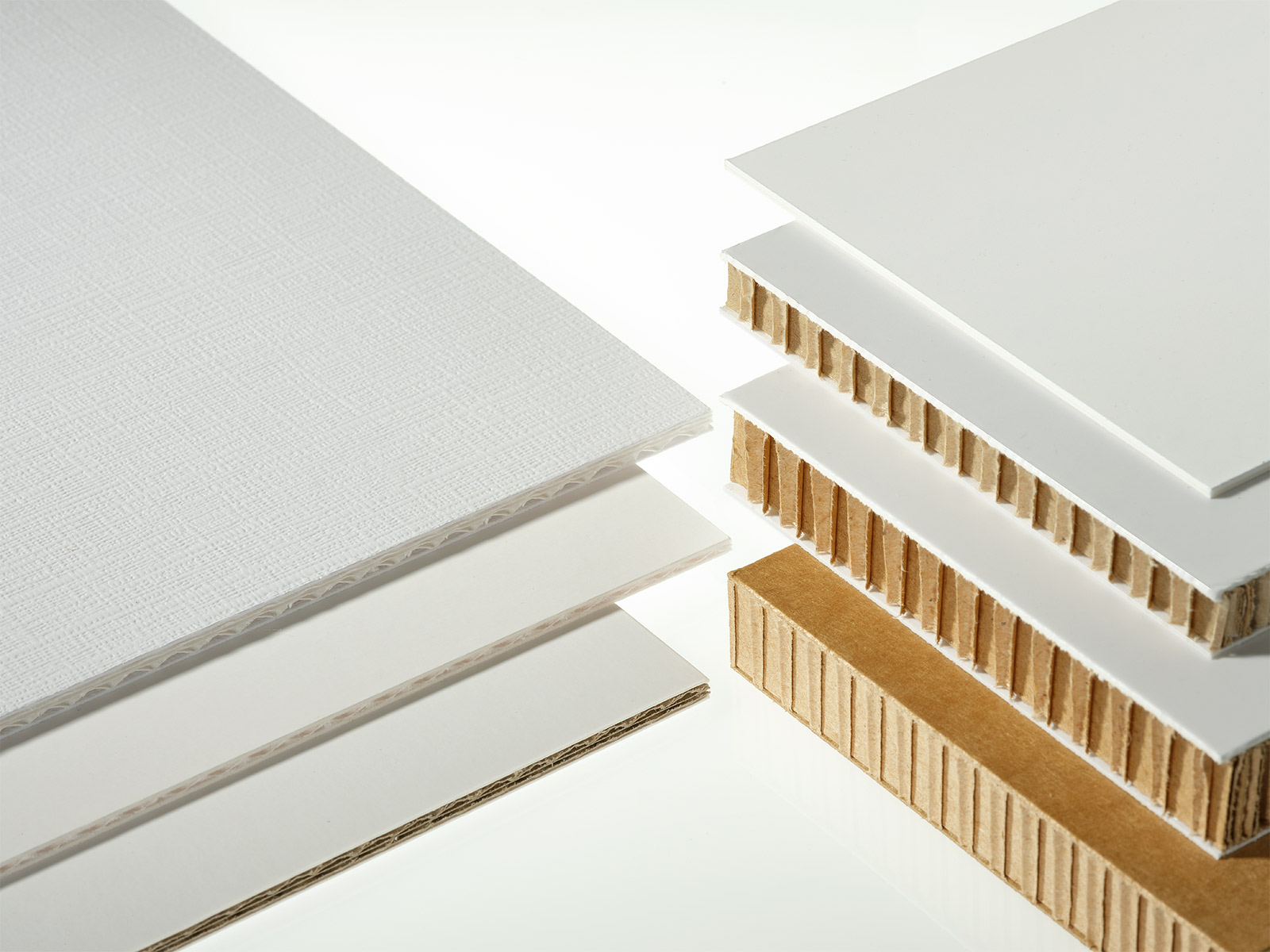

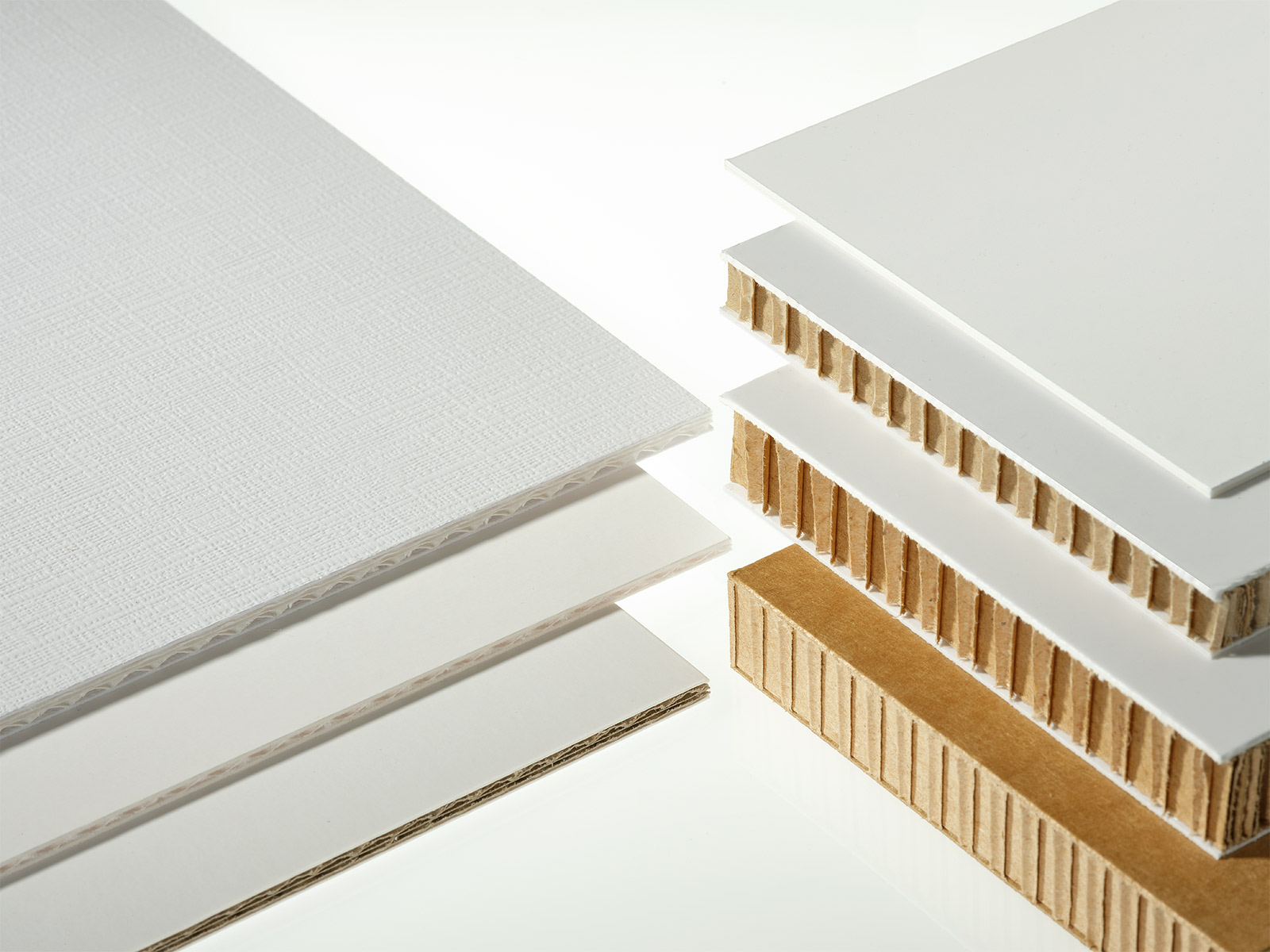

3.1 Paper-Based Boards and Composite Materials

Paper-based boards remain the go-to substrate for rigid box production due to their cost-effectiveness, printability, and wide availability. However, manufacturers have significantly upgraded traditional cardboard by creating composite boards that include layers of laminated paper or plastic coatings. This approach boosts tear resistance and prevents moisture penetration, making them ideal for premium packaging such as cosmetics, luxury goods, and electronics.

3.2 Plastics and Foams

Although sustainability is a key concern, plastics and foam materials such as PET, PE, and EVA still have significant applications in protective packaging. These materials come with:

1. High impact resistance

2. Lightweight nature

3. Excellent cushioning properties

By combining plastics or foams with paper-based layers, manufacturers can create hybrid materials that maintain a balance between rigidity and cushioning. This ensures delicate items—like glass bottles or electronics—remain secure through shipping and handling.

3.3 Biodegradable and Eco-Friendly Materials

The push towards sustainable packaging is stronger than ever, spurred by consumer demand and growing environmental regulations. As a result, companies are looking at plant-based films, recycled boards, and other biodegradable materials to lessen environmental impact. These sustainable alternatives can still meet rigid box performance requirements if paired with advanced engineering techniques, such as heat sealing or water-based adhesives.

4. Benefits of High-Performance Materials in Automatic Rigid Box Production

4.1 Enhanced Structural Integrity

By selecting higher-grade materials, manufacturers significantly reduce the likelihood of warping or crushing during transport and storage. Rigid box forming machines can operate at higher speeds because the materials are more resilient to mechanical stress.

4.2 Improved Visual Appeal

Packaging is often the first impression a consumer has of a product. High-performance materials can be laminated or embossed, providing a premium finish. The enhanced printing surface also helps in creating vibrant, high-resolution brand designs and logos.

4.3 Compatibility with Advanced Machinery

Automation in rigid box forming relies on precise material handling. Materials with consistent thickness and stiffness are easier to feed, fold, and glue using PLC-controlled or robot-assisted systems. This reliability drives down manufacturing defects and ensures higher throughput.

4.4 Reduced Waste and Cost-Efficiency

Although high-performance materials might initially appear more expensive, their durability and consistency can lower overall production costs by minimizing waste and rework. Because fewer defective boxes need to be discarded, this ultimately reduces the cost per unit.

5. Challenges and Innovations

5.1 Balancing Cost and Quality

While high-performance materials offer countless benefits, they can also add to production costs. Innovations in material science are focusing on creating cost-effective composites that mimic the properties of more expensive substrates without the added price tag.

5.2 Environmental Concerns

Amid increasing consumer awareness about the environmental impact of plastics, finding biodegradable or recyclable high-performance materials becomes crucial. Brands that effectively integrate eco-friendly substrates into their automated rigid box forming lines can expect to bolster their reputation and appeal to a wider market segment.

5.3 Integration of Smart Technologies

Emerging solutions in the packaging sector include the incorporation of IoT sensors, machine vision systems, and real-time quality checks. Pairing these technologies with high-performance materials can drastically reduce error rates, as advanced systems can detect even the smallest deformities or alignment issues on-the-fly.

6. Future Trends in High-Performance Materials for Rigid Box Forming

Looking ahead, sustainability, functionality, and technological integration will be the pillars driving the development of new materials:

1. Sustainable Packaging: The emphasis on reducing carbon footprint and plastic waste will encourage the creation of more compostable or recyclable materials that do not compromise on performance.

2. Multi-Functional Materials: Manufacturers will continue experimenting with moisture-resistant, anti-static, and antibacterial properties to cater to specialized needs, such as pharmaceutical or premium food packaging.

3. Automation and Speed: As rigid box forming machines become faster and more precise, materials must evolve to handle rapid production speeds and higher levels of stress during the forming process.

7. A Word About Dongguan Pinchuang

In the quest for superior, automated packaging solutions, Dongguan Pinchuang Automation Equipment Co., Ltd. (Pinchuang) stands out as a leading innovator. Established in 2015, Pinchuang has leveraged an experienced R&D team—with over 20 years of combined expertise—to develop cutting-edge automatic rigid box forming machines. With a portfolio of CE and EAC-certified products, the company exports its machines worldwide, providing solutions that are not only high in automation and precision, but also compatible with various high-performance materials. By collaborating with well-known universities and continuously refining its technology, Pinchuang ensures that its machines stay ahead of the curve—helping clients reduce costs, minimize errors, and boost overall production efficiency.

8. Conclusion

High-performance materials have emerged as key drivers in the automatic rigid box forming landscape. From improving structural integrity and enhancing visual appeal to enabling rapid production speeds, these materials are transforming the packaging industry. As we look to the future, innovations in sustainability, multi-functionality, and automation will further expand the possibilities of packaging design and manufacturing.

For businesses aiming to stay competitive, exploring and integrating these advanced materials—paired with high-quality automatic rigid box forming machines—can make a profound difference in both brand presentation and bottom-line results. Whether you are a startup brand or a global enterprise, investing in new-generation, eco-friendly, and performance-oriented materials is the key to elevating customer experience and meeting evolving consumer expectations.

If you are looking for automated solutions that seamlessly adapt to a range of high-performance materials, Dongguan Pinchuang provides a robust selection of full-automation equipment designed to keep pace with modern demands. Partner with an industry leader dedicated to innovation and quality, and discover how to unlock new opportunities in packaging precision and efficiency.

English

English