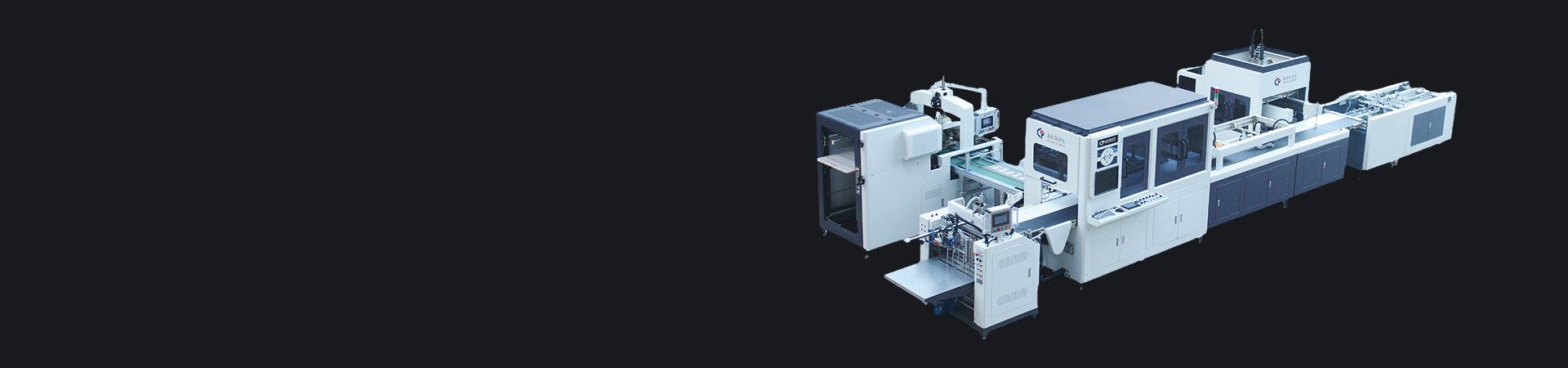

Automatic Case Making Machine( Yamaha Visual Position Type) PC-500P:

Book Case Making Machine Characteristics:

1.machine use 10 kg yamaha brand for High precision

2. PLC Program Control + Touching Screen

3. double Japanese brand camera with 10 million pixels

4 .Automatic double detection function for paper feeding part

5 .1100*600mm (L*W) big cover size can be made

6. Short Machine design for easy operation

7 .Omron PLC, Dell Computer, Airtac Cylinder, SMC electromagnetic valve etc used in this Paper Case Making Machine.

8 .High Accuracy

Machine functions:

This machine has adopted an auto feeder to feed paper and an auto cardboard positioning system.It can detect double sheet in ultrasonic manner and press the angless with a gas controller.It also can transfer the materials in a table-type pile.This machine is characterized by running fast and convenience in operation.It is a latest machine to manufacturer,perfect book covers,notebooks,book-cover,calendars,hangling calendars,files,etc.

Machine features:

1.The feeder in this machine adopts back-push feeding system,which is controlled penumatically,and its structure is simple and reasonable;

2.The width between stacker and feeding table is adjusted concentrically in the centre.The operation is very easy without tolerance;

3.The cardboard feeding table is controlled by linear g uide line and stepping motor,its location is correct and quick;

4.In the cardboard feeding table,the machine can automatically stop when lack of paper to reduce the paper waste;

5.Big-power air sucker is adopted for conveyor belt to feed the paper more stably and accurately;

6.Paper feeding and positioning system adopt imported high-precise photoeletric control device to make the paper and cardboard location more accurate and stable;

7.The automatic four-edge folding machine adopts special automatic angle-repair,edge-repair to ensure the qualification of finished products;

8.The delievery table is a lifting table of automatic control smooth delievery.

Production Flow:

Machine Application:

PC-500P can automatic finished the wine box cover, Cigarettes box cover, moon cakes box cover, tea box cover, mobile phone box cover, underwear box cover, handicrafts box cover, cosmetic box cover, file folders, calendars, book cover etc.

Technical Parameter:

| Model | PC-500P |

| Paper Size | L 140-1100mm |

| W 100-560mm |

| Paper thickness | 80-300g/㎡ |

| Paper Stacking Height | 300mm |

| Max Finished Cover Size | L 1000* W 500mm |

| Min Finished Cover Size | L 200* W 100 mm |

| Seperated Cardboard Quantity | 1-6 pcs |

| Min Middle Strip | 10mm |

| Cardboard Thickness | 1-4mm |

| Production Speed | 20-30pcs/min |

| Position Precision | ±0.1mm |

| Air Supply | 10L/min 0.8MPa |

| Motor Power | 10.5kw/380v 3phase |

| Heating Power | 6kw |

| Machine Weight | 3000kg |

| Machine Dimension | 10500mm*2050mm*2050mm |

Detail Image Of Automatic Hard Cover Case Making Machine PC-500P

Pre-Sales Service

* Inquiry and consulting support.

* Sample testing support.

* View our Factory.

After-Sales Service

* Training how to instal the machine, training how to use the machine.

* Engineers available to service machinery overseas.

*One year machine warranty.

Packaging details&delievery:

The normal package is wooden box(Size: L*W*H). According to differrent countries cusomer's request the wooden box will be fumigated or not.If container is too tigher,we will use pe film for packing or pack it according to customers special request.

FAQ:

1: What about the machine warranty?

We offer 1 year warranty for all the customers. If any spare parts broken by itself not wrong operation, we will send the free replacement by free DHL for any customer.

2:How to install machine if we buy the machine?

We have after service team for machine installation. Technician can travel abroad for customer machine installation and training.

3: what to do if machine stuck for some problems?

You send us the machine problem video and machine problem parts, we will check with our technician immediately to find the solution for your problem.

4: What spare parts you will give if we buy machine?

We usually offer all the machine extra spare parts like the cylinder and The electromagnetic valvem sensor, mold for the box, suction nozzle, blade etc. Each machine has extra spare parts with basic tool.

5: what your company payment terms

We accept TT and LC payment.

6: what if we pay money but no shipment?

We are old company here and we are honest manufacturer . If you worry money paid but no shipment, we can send all your the packaging and shipping container loading picture. Or you can ask your Chinese friend come to inspect our factory and your machine.

English

English