Introduction

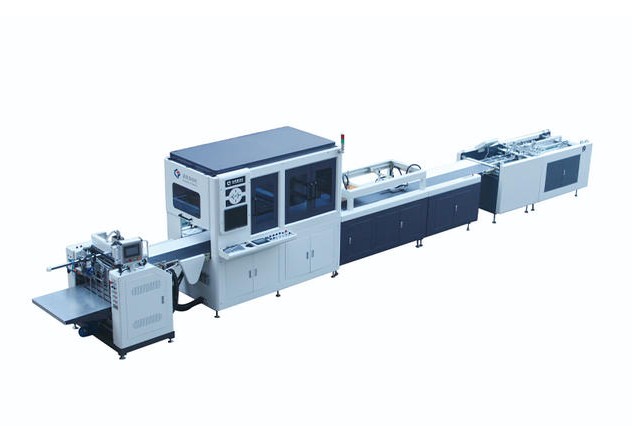

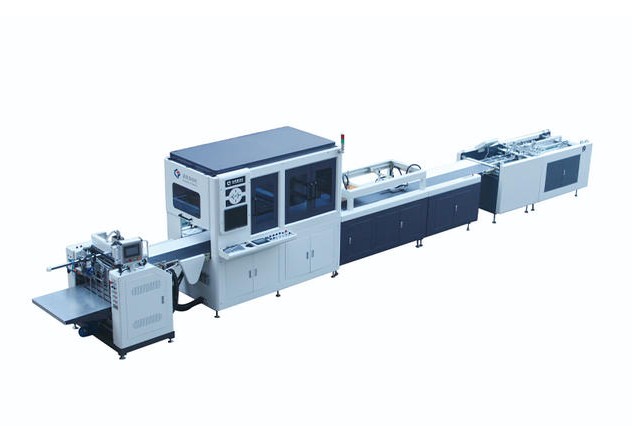

In today's environmentally conscious world, sustainable practices have permeated nearly every aspect of business. The packaging industry is no exception, and adopting eco-friendly solutions is rising. As more companies seek to reduce their carbon footprint and embrace sustainable packaging, the importance of using sustainable materials and techniques in Case Making Machines has come to the forefront.

This article delves into Case Making Machines, focusing on sustainability. We will explore using sustainable materials and innovative techniques in case-making, highlighting their compatibility with Case Making Machines. Furthermore, we will discuss how these practices can provide cost-effective, eco-friendly packaging solutions to meet the needs of businesses today.

Sustainable Materials in Case-Making

When it comes to the production of cases for packaging, traditional materials like plastics and non-recycled paper have been the go-to choices for decades. However, with increasing environmental concerns, businesses are turning to sustainable materials such as recycled paper, bio-based adhesives, and eco-friendly inks.

Recycled Paper

Recycled paper is a critical player in sustainable case-making. Its production requires fewer resources than conventional paper, making it an excellent choice for eco-conscious businesses. The good news is that Case Making Machines are fully compatible with recycled paper, allowing seamless integration.

Bio-Based Adhesives

Bio-based adhesives are another sustainable option in case-making. These adhesives are derived from renewable resources, reducing the environmental impact associated with case production. Businesses using Case Making Machines can quickly implement these adhesives in their processes.

Eco-Friendly Inks

Eco-friendly inks, often water-based or soy-based, offer a greener alternative for printing designs and logos on cases. These inks are low in volatile organic compounds (VOCs), reducing air pollution. When incorporated into Case Making Machines, they contribute to the overall sustainability of the packaging process.

Innovative Techniques for Eco-Friendly Case Making

While sustainable materials lay the foundation for eco-friendly case-making, innovative techniques are crucial in achieving environmentally responsible packaging solutions. Let's explore some of these techniques and their compatibility with Case Making Machines.

Water-Based Inks

Water-based inks have gained popularity for their minimal impact on the environment. Unlike solvent-based inks, they contain fewer volatile organic compounds (VOCs) and do not emit harmful toxins into the air during printing. Case Making Machines can efficiently incorporate water-based inks for vibrant, eco-conscious case designs.

Energy-Efficient Processes

Efficiency is critical to sustainability. Energy-efficient processes in Case Making Machines help reduce power consumption and minimize the carbon footprint. Look for machines that have advanced energy-saving features, such as automatic shut-off when not in use or optimized heating elements, to ensure sustainability in your case manufacturing.

Lean Manufacturing Principles

Lean manufacturing is a systematic approach to reducing waste in the production process. Case Making Machines can help companies save resources and reduce costs by minimizing unnecessary steps and materials. Implementing lean principles in case-making boosts sustainability and enhances overall efficiency.

Modular Design for Adaptability

Modular Case Making Machines are designed for adaptability. They can be reconfigured for various case sizes and styles, allowing businesses to produce only what is needed. This minimizes waste and optimizes resources, a critical aspect of eco-friendly packaging production.

Incorporating these techniques into the operation of your Case Making Machine can significantly contribute to more sustainable packaging practices.

Case Studies

The transition to sustainable case-making is more than merely theoretical; many businesses have already implemented these practices and achieved remarkable results. Let's examine case studies highlighting the real-world benefits of sustainable materials and techniques in Case Making Machines.

Case Study 1: A Greener Packaging Manufacturer

Company X, a packaging manufacturer, switched to sustainable materials and techniques with a fully automatic case-making machine. They reduced their carbon footprint by 20% by adopting recycled paper and water-based inks. This change aligned with their eco-friendly values and attracted environmentally conscious customers, leading to a 15% increase in sales.

Case Study 2: Efficiency and Sustainability

Company Y, a leader in packaging solutions, implemented lean manufacturing principles in combination with modular Case Making Machines. They reduced material waste by 30% and cut energy consumption by 15%. These changes improved their bottom line and positioned them as a sustainable packaging provider.

These case studies demonstrate that adopting sustainable materials and techniques is not only environmentally responsible but can also be financially rewarding.

Selecting the Right Case-Making Machine

Choosing the proper Case Making Machine is critical in achieving eco-friendly packaging solutions. When making this decision, it's essential to consider several factors to ensure the machine aligns with your sustainability goals.

Sustainability Features

One of the primary considerations is the machine's built-in sustainability features. Look for case-making machines explicitly designed to work with recycled materials, bio-based adhesives, and eco-friendly inks. Devices with energy-saving modes and adaptable, modular designs should be on your radar.

Supplier Engagement

Engage with your Case Making Machine supplier to discuss your sustainability requirements. Ask about the machine's compatibility with eco-friendly practices and adaptability to sustainable materials and techniques. A reliable supplier should be able to guide eco-conscious choices.

Total Cost of Ownership

Assess the total cost of ownership when evaluating Case Making Machines. While eco-friendly machines might have a slightly higher upfront cost, they can often deliver long-term savings through reduced material waste, lower energy consumption, and enhanced efficiency. Consider your sustainability goals alongside financial factors.

User Training and Support

Ensure your team receives proper training in operating the Case Making Machine with sustainability in mind. Knowledgeable operators can maximize the machine's potential for eco-friendly production. Additionally, verify that your supplier offers adequate technical support for sustainable case-making.

Scalability

Think about your future needs. As your business grows, you may need to increase case production. Choose a Case Making Machine that can scale with your production requirements, ensuring you can maintain sustainable practices as your company expands.

Environmental Certifications

Look for machines with environmental certifications that vouch for their sustainability features. Certifications like ISO 14001 or Energy Star can guarantee that the device meets specific ecological standards.

Overcoming Challenges

Transitioning to sustainable case-making may pose some challenges, but careful planning and commitment can overcome these challenges.

Material Sourcing

Sourcing sustainable materials can be a challenge, but with increased demand, more suppliers are offering these options. Build relationships with sustainable material suppliers and explore regional sourcing to minimize the environmental impact of transportation.

Training and Adaptation

Proper training is essential to optimize your Case Making Machine for sustainability. Invest in training for your team to ensure they can operate the machine efficiently while adhering to eco-friendly practices.

The Business Case for Sustainability

While the shift towards eco-friendly packaging and sustainable Case Making Machines is driven by environmental responsibility, a strong business case must be made. Embracing sustainability in your case-making process can provide numerous advantages beyond a reduced ecological footprint.

Competitive Advantages

In today's competitive market, businesses that position themselves as environmentally responsible can stand out. The eco-conscious consumer segment continues to grow, and many consumers actively seek products and services that align with their values. By offering eco-friendly packaging solutions, you can attract a broader customer base and gain a competitive edge.

Marketing Benefits

Eco-friendly practices can be a powerful marketing tool. Use your commitment to sustainability as a focal point in your marketing efforts. Highlight how using sustainable materials and techniques in your Case Making Machines contributes to a greener future. Transparent and authentic sustainability efforts can enhance your brand's reputation.

Long-Term Benefits and Return on Investment (ROI)

Investing in sustainable materials and techniques and Case Making Machines designed for eco-friendliness may involve initial costs. However, the long-term benefits far outweigh the upfront investment. Reduced material waste, lower energy consumption, and increased efficiency contribute to substantial savings over time. Assess the ROI of sustainability measures and recognize that they can enhance your bottom line.

Conclusion

In a world where sustainability is becoming an integral part of business strategy, adopting eco-friendly packaging solutions is not just an option; it's a necessity. Case Making Machines plays a pivotal role in this transition. By integrating sustainable materials and innovative techniques into your case-making process and selecting the proper Case Making Machine, you can achieve eco-friendly packaging that meets the expectations of modern consumers.

Remember that sustainability benefits the environment and provides a compelling business case. You can gain a competitive advantage, enhance your brand's image, and achieve a positive ROI by investing in sustainable packaging solutions.

As the demand for eco-friendly packaging continues to rise, the time is ripe to embrace sustainability in your case-making operations. By doing so, you'll contribute to a greener planet and ensure your business's long-term success.

English

English